Microencapsulation of Oxidation Sensitive Oils – Physical Protection Mechanism

Seiten

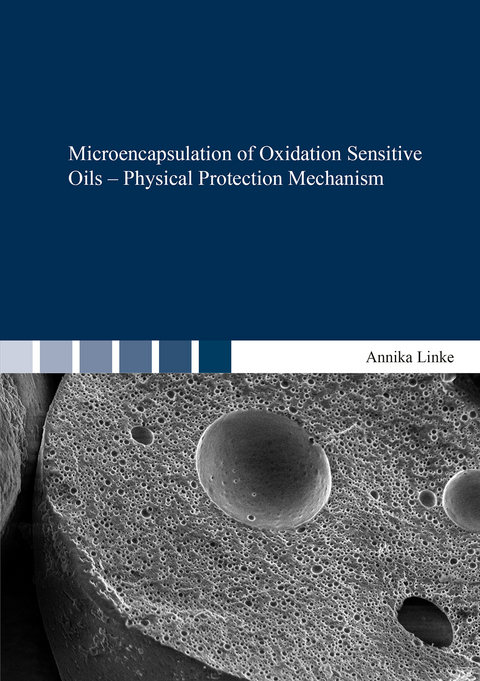

Microencapsulation aims to protect oxidation sensitive oils by embedding them as droplets in a solid matrix that builds a physical barrier to the environmental oxygen. Even though oil and oxygen are physically separated from each other, such particle systems do oxidize. Two “oxygen sources” potentially react with the oil: the internal and the external oxygen. The internal oxygen is incorporated in the spray dried powder, whereas the external oxygen is in the environment surrounding the particle. In order to understand the main causes for oxidation of such systems, the thesis has been divided into three parts.

In Part I the contribution of the internal and external oxygen to oxidation of the particle system has been studied by preparing feed emulsions and final powder under atmospheric and inert conditions and storing them under vacuum and in vials.

In Part II the origin of the non-encapsulated oil and its contribution to the overall oxidation of the system has been investigated. Some oil droplets are not fully encapsulated and are in contact with the powder surface. The so-called surface or non-encapsulated oil is exposed to the environment and can react unhindered with the external oxygen.

In part III the effect of powder properties such as particle size, oil droplets size and oil load on the reaction of the external oxygen with the encapsulated oil has been analysed. In addition to the experimental approach, a theoretical simulation has been proposed to model the oxygen diffusion into the particle based on Fickian diffusion. The reaction kinetics of the oil has been studied to relate the hydroperoxide formation rate to the oxygen level. Comparing experimental with calculated data allowed further understanding the physical protection mechanism.

In Part I the contribution of the internal and external oxygen to oxidation of the particle system has been studied by preparing feed emulsions and final powder under atmospheric and inert conditions and storing them under vacuum and in vials.

In Part II the origin of the non-encapsulated oil and its contribution to the overall oxidation of the system has been investigated. Some oil droplets are not fully encapsulated and are in contact with the powder surface. The so-called surface or non-encapsulated oil is exposed to the environment and can react unhindered with the external oxygen.

In part III the effect of powder properties such as particle size, oil droplets size and oil load on the reaction of the external oxygen with the encapsulated oil has been analysed. In addition to the experimental approach, a theoretical simulation has been proposed to model the oxygen diffusion into the particle based on Fickian diffusion. The reaction kinetics of the oil has been studied to relate the hydroperoxide formation rate to the oxygen level. Comparing experimental with calculated data allowed further understanding the physical protection mechanism.

| Erscheinungsdatum | 10.06.2023 |

|---|---|

| Reihe/Serie | Berichte aus der Lebensmitteltechnologie |

| Verlagsort | Düren |

| Sprache | englisch |

| Maße | 148 x 210 mm |

| Gewicht | 317 g |

| Themenwelt | Technik ► Lebensmitteltechnologie |

| Schlagworte | microencapsulation • Oxidation • Particle technology • Spray Drying |

| ISBN-10 | 3-8440-9119-X / 384409119X |

| ISBN-13 | 978-3-8440-9119-9 / 9783844091199 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

Mehr entdecken

aus dem Bereich

aus dem Bereich

Technologie, Chemie, Mikrobiologie, Analytik, Bedeutung, Recht

Buch | Hardcover (2023)

Verlag Eugen Ulmer

CHF 169,00