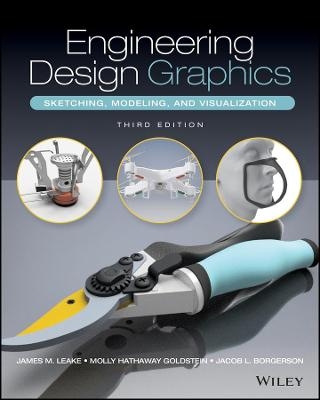

Engineering Design Graphics

John Wiley & Sons Inc (Verlag)

978-1-119-49043-2 (ISBN)

In the newly revised Third Edition of Engineering Design Graphics: Sketching, Modeling, and Visualization, renowned engineering graphics expert James Leake delivers an intuitive and accessible guide to bringing engineering concepts and projects to visual life. Including updated coverage of everything from freehand sketching to solid modeling in CAD, the author comprehensively discusses the tools and skills you'll need to sketch, draw, model, document, design, manufacture, or simulate a project.

1 ENGINEERING DESIGN 1

INTRODUCTION 1

ASPECTS OF ENGINEERING DESIGN 1

ANALYSIS AND DESIGN 4

PRODUCT ANATOMY 5

DESIGN PHASES 5

DESIGN PROCESS OVERVIEW 6

NEEDS ASSESSMENT 7

PROBLEM DEFINITION 7

BACKGROUND RESEARCH 7

DESIGN CRITERIA 8

DESIGN CONSTRAINTS 8

ALTERNATIVE SOLUTIONS 9

ANALYSIS 12

EVALUATION AND SELECTION 12

SPECIFICATION 16

COMMUNICATION 20

Written Reports 20

Recommended report-writing steps 20

Oral Presentations 21

BEGINNING VERSUS INFORMED DESIGNER PATTERNS (SIDEBAR) 23

CONCURRENT ENGINEERING 23

Design for Manufacture and Assembly 25

TEAMWORK 26

QUESTIONS 27

2 HUMAN-CENTERED DESIGN AND DESIGN THINKING 29

INTRODUCTION 29

ENGINEERING DESIGN, ART, AND SCIENCE

Introduction

Design: a fundamental human activity

Engineering Design from 1400 to 1900

Engineering Education after 1900

TWO DESIGN PARADIGMS

Design as rational problem solving

Design as a reflective practice

WICKED PROBLEMS

DIVERGENT AND CONVERGENT QUESTIONING

DOUBLE DIAMOND DESIGN PROCESS

HUMAN-CENTERED DESIGN

DESIGN THINKING

Introduction

Three spaces of innovation

Inspiration

Observation

Empathy

Ideation

Empathy

Ideation

Brainstorming

Prototyping

Implementation

Test and iterate

T-shaped individuals (sidebar)

Radical collaboration

QUESTIONS

3 PRODUCT DISSECTION

INTRODUCTION

PRODUCT SUITABILITY

PRODUCT DISSECTION PROCEDURE

PRE-DISSECTION ANALYSIS

DISSECTION

Craftsman locking pliers disassembly steps

PRODUCT DOCUMENTATION

PRODUCT ANALYSIS

PRODUCT IMPROVEMENT

REASSEMBLY

COMMUNICATION

QUESTIONS

4 FREEHAND SKETCHING

INTRODUCTION

SKETCHING TOOLS AND MATERIALS

SKETCHING TECHNIQUES

Line Techniques

Sketching Straight Lines

Sketching Circles

Sketching Ellipses

PROPORTIONING

Estimating Dimensions of Actual Objects

Partitioning Lines

INSTRUMENT USAGE—TRIANGLES

Parallel Lines

Perpendicular Lines

LINE STYLES

QUESTIONS

5 PLANAR PROJECTIONS AND PICTORIAL VIEWS

PLANAR PROJECTIONS

Introduction

Classification of Planar Projections: Projector Characteristics

Preliminary Definitions

Block coefficient

Classification of Planar Projections: Orientation of Object with Respect to Projection Plane

Further Distinctions Between Parallel and Perspective Projections

Classes of Parallel Projections

OBLIQUE PROJECTIONS

Oblique Projection Geometry

Oblique Projection Angle

Classes of Oblique Projections

Oblique projection angle in 2D

Receding Axis Angle

ORTHOGRAPHIC PROJECTIONS

Orthographic Projection Geometry

Orthographic Projection Categories

AXONOMETRIC PROJECTIONS

ISOMETRIC PROJECTIONS

Isometric Drawings

Multiview Projections

INTRODUCTION TO PICTORIAL SKETCHING

OBLIQUE SKETCHES

Introduction

Axis Orientation

Receding Axis Scale

Object Orientation Guidelines

Sketching procedure for a simple extruded shape (see Figure 5-37)

Step-by-step cabinet oblique sketch example for a cut block (see Figure 5-38)

Step-by-step cavalier oblique sketch example for an object with circular features (see Figure 5-39)

ISOMETRIC SKETCHES

Introduction

Axis Orientation

Isometric Scaling

Isometric Grid Paper

Object Orientation Guidelines

Step-by-step isometric sketch example for a cut block (see Figure 5-46)

Circular Features in an Isometric View

Step-by-step isometric sketch example for a cylinder (see Figure 5-47)

Step-by-step isometric sketch example for a box with holes on three faces (see Figure 5-48)

Step-by-step sketch example for an object with circular features (see Figure 5-49)

Chapter review: pictorial sketching scalability

QUESTIONS

6 PERSPECTIVE PROJECTIONS AND PERSPECTIVE SKETCHES

PERSPECTIVE PROJECTION

Historical Development

Perspective Projection Characteristics

Classes of Perspective Projection

Vanishing Points

One-Point Perspective Projection

Two-Point Perspective Projection

Three-Point Perspective Projection

Perspective Projection Variables

Perspective projection using a 3D CAD system

Projection plane location

Lateral movement of CP

Vertical movement of CP

Varying distance from CP

PERSPECTIVE SKETCHES

Introduction

Terminology

One-Point Perspective Sketches

Two-Point Perspective Sketches

Proportioning Techniques

Step-by-step one-point perspective sketch example (see Figure 6-26)

Step-by-step two-point perspective sketch example (see Figure 6-27)

Summary: orientation of pictorial sketching axes (see Figure 6-28)

QUESTIONS

7 MULTIVIEWS

MULTIVIEW SKETCHING

Introduction—Justification and Some Characteristics

Glass Box Theory

Alignment of Views

Transfer of Depth

View Selection

Third-Angle and First-Angle Projection

Line Conventions

Multiview drawing of a cylinder (see Figure 7-21)

Line Precedence

Generic three multiview sketch procedure (see Figure 7-24)

Step-by-step multiview sketch example (see Figure 7-25)

Intersections and Tangency 92 Fillets and Rounds

Machined Holes

Conventional Representations: Rotated Features

Step-by-step multiview sketch example: object with complex features (see Figure 7-33)

VISUALIZATION TECHNIQUES FOR MULTIVIEW DRAWINGS

Introduction and Motivation

Treatment of Common Surfaces

Normal surfaces

Inclined surfaces

Oblique surfaces

Projection Studies

Adjacent Areas

Surface Labeling

Similar Shapes

Vertex Labeling

Analysis by Feature

Missing-Line and Missing-View Problems

QUESTIONS

8 SECTION AND AUXILIARY VIEWS

SECTION VIEWS

Introduction

Section View Process

Section Lining (Hatch Patterns)

Full Sections

Half Sections

Offset Sections

Broken-Out Sections

Revolved Sections

Removed Sections

Conventional Representations: Section Views

Conventional Representations: Thin Features

Section View Construction Process—Example 1

Section View Construction Process—Example 2

Conventional Representations: Aligned Sections

Assembly Section Views

AUXILIARY VIEWS

Introduction

Definitions

Auxiliary View Projection Theory

Auxiliary Views: Three Cases

General Sketching Procedure for Finding a Primary Auxiliary View

Step 1

Step 2

Step 3

Step 4 (optional)

Step 5

Step 6

Finding a Primary Auxiliary View of a Contoured Surface

Finding a Partial Auxiliary View, an Isometric Pictorial, and a Missing View, Given Two Views

QUESTIONS

9 DIMENSIONING AND TOLERANCING

DIMENSIONING

Introduction

Units of Measurement

Application of Dimensions

Terminology

Reading direction for dimensional values

Arrangement, placement, and spacing of dimensions

Using Dimensions to Specify Size and Locate Features

Symbols, Abbreviations, and General Notes

Dimensioning Rules and Guidelines

Prisms

Cylinders and arcs

Finish Marks

TOLERANCING

Introduction

Definitions

Tolerance Declaration

Tolerance Accumulation

Mated Parts

Basic Hole System: English Units

Basic Shaft System: English Units

Step-by-step tolerance calculation of a clearance fit using the basic hole system (see Figure 9-27)

Step-by-step tolerance calculation of an interference fit using the basic hole system (see Figure 9-28)

Preferred English Limits and Fits

Running or sliding clearance fit (RC)

Locational clearance fit (LC)

Transition clearance or interference fit (LT)

Step-by-step tolerance calculation of a clearance fit using the basic shaft system (see Figure 9-30)

Locational interference fit (LN)

Force or shrink fit (FN)

Step-by-step tolerance calculation using English-unit fit tables, basic hole system (see Figure 9-31)

Step-by-step tolerance calculation using English-unit fit tables, basic shaft (see Figure 9-32)

Preferred Metric Limits and Fits

Step-by-step tolerance calculation using metric-unit fit tables, hole basis (see Figure 9-39)

Step-by-step tolerance calculation using metric-unit fit tables, shaft basis (see Figure 9-40)

Tolerancing in CAD

QUESTIONS

10 CAD: SOLID MODELING

INTRODUCTION

Computer-Aided Design

Categories of CAD Systems

Computer-aided drawing

Solid modeling

Topology (Sidebar)

Parametric modeling

Direct modeling

Surface Modeling – NURBS and Freeform

Building Information Modeling (BIM) (Sidebar)

CAD Viewing and Display

PARAMETRIC MODELING

Introduction

Terminology

Part Modeling

Introduction

Sketch mode

Feature creation

Part editing

Part creation process (see Figure 10-32)

Assembly Modeling

Introduction

Joints

CAD libraries

Advanced Modeling Strategies

Cloud-Based CAD

QUESTIONS 241

11 CAD: NURBS AND FREEFORM SURFACE MODELING

NURBS SURFACE MODELING

Introduction

Parametric Curves and Cubic Splines

Parametric representation of a curve (sidebar)

Bézier Curves

B-Splines

NURBS

Surfaces

Curvature

Continuity

Class A Surfaces

FREEFORM SURFACE MODELING

Introduction

Polygon meshes and polygonal modeling

Subdivision surfaces

NURBS Limitations

T-Splines

The Bézier Award (Sidebar)

QUESTIONS

12 PRODUCT DOCUMENTATION

WORKING DRAWINGS

Model-based definition

DETAIL DRAWINGS

ASSEMBLY DRAWING VIEWS

BILL OF MATERIALS AND BALLOONS

SHEET SIZES

TITLE BLOCKS

BORDERS AND ZONES

REVISION BLOCKS

DRAWING SCALE

TOLERANCE NOTES

STANDARD PARTS

WORKING DRAWING CREATION USING PARAMETRIC MODELING SOFTWARE

Extracting a detail drawing from a parametric part model (see Figure 12-16)

Using existing part models to create an assembly model (see Figure 12-17)

Extracting a sectioned assembly drawing (see Figure 12-18)

Creating an exploded view (see Figure 12-19)

Creating an exploded view drawing with parts list and balloons (see Figure 12-20)

INDUSTRY SPOTLIGHT: FISKARS GROUP

QUESTIONS

13 ADDITIVE MANUFACTURING

INTRODUCTION

AM TECHNOLOGIES

Vat photopolymerization

Material extrusion

Powder bed fusion

Material jetting

CLASSIFICATION OF AM TECHNOLOGIES

3D PRINTER FILE FORMATS

STL REPAIR TOOLS

CHARACTERISTICS OF AM SYSTEMS

Part orientation

Support structure

Hatch style

LOW-COST AM

Industrial category AM

Professional category 3D printers

Consumer (home and hobby, desktop) category 3D printers

DESIGN FOR ADDITIVE MANUFACTURING

Design for conventional manufacturing processes

Design for AM

QUESTIONS

9 3D SCANNING

REVERSE ENGINEERING

3D SCANNING

Introduction

3D Scanner Pipeline

Mesh terminology

3D Scanning Technologies

Contact-based scanners

Noncontact scanners

Laser triangulation

Structured Light

Reality Capture

Photogrammetry

Time of Flight

Reverse Engineering Software

Mesh reconstruction (or point processing)

NURBS surface modeling from scan data

Parametric CAD model from scan data

QUESTIONS

15 SIMULATION

UPFRONT ANALYSIS

FINITE ELEMENT ANALYSIS

Modeling and Meshing

Boundary Conditions

Contour plot

Results

FEA workflow

GENERATIVE DESIGN

Generative design workflow

DYNAMICS SIMULATION SOFTWARE

Dynamics Simulation Software Demonstration

QUESTIONS

A ANSI PREFERRED ENGLISH LIMITS AND FITS

B ANSI PREFERRED METRIC LIMITS AND FITS

INDEX 3

DRAWING SHEETS

| Erscheinungsdatum | 18.09.2018 |

|---|---|

| Co-Autor | Jacob L. Borgerson |

| Verlagsort | New York |

| Sprache | englisch |

| Maße | 203 x 249 mm |

| Gewicht | 794 g |

| Themenwelt | Informatik ► Weitere Themen ► CAD-Programme |

| Technik ► Maschinenbau | |

| ISBN-10 | 1-119-49043-X / 111949043X |

| ISBN-13 | 978-1-119-49043-2 / 9781119490432 |

| Zustand | Neuware |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich