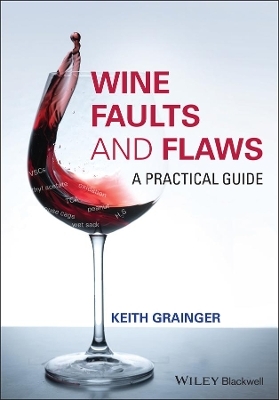

Wine Faults and Flaws

Wiley-Blackwell (Verlag)

978-1-118-97906-8 (ISBN)

2022 Winner of the OIV Award in the Oenology category

An essential guide to the faults and flaws that can affect wine

Written by the award-winning wine expert, Keith Grainger, this book provides a detailed examination and explanation of the causes and impact of the faults, flaws and taints that may affect wine. Each fault is discussed using the following criteria: what it is; how it can be detected by sensory or laboratory analysis; what the cause is; how it might be prevented; whether an affected wine is treatable, and if so, how; and the science applicable to the fault.

The incidences of faulty wines reaching the consumer are greater than would be regarded as acceptable in most other industries. It is claimed that occurrences are less common today than in recent recorded history, and it is true that the frequency of some faults and taints being encountered in bottle has declined in the last decade or two. However, incidences of certain faults and taints have increased, and issues that were once unheard of now affect many wines offered for sale. These include ‘reduced’ aromas, premature oxidation, atypical ageing and, very much on the rise, smoke taint.

This book will prove invaluable to winemakers, wine technologists and quality control professionals. Wine critics, writers, educators and sommeliers will also find the topics highly relevant. The wine-loving consumer, including wine collectors will also find the book a great resource and the basis for discussion at tastings with like-minded associates.

Reviews

I read this book avidly from cover to cover. I’ll dip into it for future reference as required, which is how many will employ it. Meanwhile, I learned a great deal, and it now influences how I think about wine evaluation.

I commend this excellent new book to you. Consider it an investment. Paul Howard, Wine Alchemy

ABOUT THE AUTHOR Keith Grainger is a wine writer, educator and consultant in wines and wine technology. His last book Wine Production and Quality, 2nd Edition (with co‑author Hazel Tattersall) won the Gourmand Award for the Best Wine Book for Professionals in 25 Years.

ACKNOWLEDGMENTS

PREFACE

INTRODUCTION

CHAPTER 1 Faults, Flaws, Off-Flavours, Taints, and Undesirable Compounds

1.1 Introduction

1.2 Advances in wine technology in recent decades

1.3 Changes in markets and the pattern of wine consumption in recent decades

1.4 The possible impact of some fault compounds upon human health

1.5 Sulfur dioxide and other possible allergens

1.6 Faults and taints

1.7 Distinguishing between faults and flaws

1.8 Sensory detection (perception) thresholds and sensory recognition thresholds

1.9 Consumer Rejection Thresholds (CRTs)

1.10 Basic categories of wine faults

1.11 Flaws

1.12 The incidence of wine faults

1.13 'Faulty' wines that exude excellence

1.14 Final reflections

CHAPTER 2 Wine Tasting

2.1 Introduction

2.2 Anosimics, the Fatigue Effect, and Supertasters

2.3 Tasting conditions, equipment and glassware

2.4 The use of a structured tasting technique, and detection of faults

2.5 Appearance

2.6 Nose

2.7 Palate

2.8 Assessment of Quality

2.9 Assessment of Readiness for drinking/potential for ageing

2.10 Grading wine – the award of points

2.11 Blind tasting

2.12 Final reflections

CHAPTER 3 Chloroanisoles, Bromoanisoles, Halophenols

3.1 Introduction

3.2 Haloanisole contaminations in the food, drinks, water, and pharmaceutical industries

3.3 Haloanisole contamination of wines

3.4 The economic and reputational costs to wine producers and the wine industry

3.5 Sensory characteristics and detection of haloanisoles in wine

3.6 The haloanisoles responsible and their detection thresholds

3.7 The formation pathways of haloanisoles from halophenols

3.8 Contamination of cork with TCA and other chloroanisoles

3.9 The cork industry in the dock

3.10 The cork industry begins to address the issues

3.11 The cork industry’s recent initiatives for haloanisole prevention and extraction

3.12 Winery and cooperage sources of haloanisole contamination in wines

3.13 Laboratory analysis for TCA and other haloanisoles in corks and wine

3.14 Prevention of haloanisole contamination of wineries and wines

3.15 Treatment of wines contaminated with haloanisoles

3.16 Chlorophenols and bromophenols as taints

3.17 'Musty' taints unrelated to halophenols and haloanisoles.

3.18 Final reflections

CHAPTER 4 Brettanomyces (Dekkera) and Ethyl phenols

4.1 Introduction

4.2 Background and history

4.3 The Brett Controversy

4.4 Sensory characteristics, and detection of Brettanomyces related compounds in wine

4.5 The origins of Brettanomyces and formation of related compounds in wines

4.6 The danger periods and favourable conditions for the growth of Brettanomyces

4.7 Why are Brettanomyces related compounds found mostly in red wines?

4.8 Prevention – Formulation and implementation a Brett Control Strategy.

4.9 Laboratory Analysis for Brettanomyces and volatile phenols

4.10 Treatment of affected wines

4.11 What the future might hold for microbiological methods to inhibit Brettanomyces?

4.12 Final reflections

CHAPTER 5 Oxidation, Premox and Excessive Acetaldehyde

5.1 Introduction

5.2 Oxidation in must and wine

5.3 Sensory characteristics and detection of excess acetaldehyde and oxidation in wine

5.4 Deliberately oxidised and highly oxygenated wines

5.5 Metal ions and substrates for oxidation

5.6 Enzymatic oxidation

5.7 Chemical oxidation

5.8 Microbial oxidation

5.9 Acetaldehyde

5.10 Sotolon

5.11 Oxygen management in winemaking

5.12 Oxygen uptake during cellar operations

5.13 Containers and closures

5.14 Pinking

5.15 Premature oxidation (Premox)

5.16 Prevention of excess acetaldehyde and oxidation

5.17 Additions of ascorbic acid – antioxidant or oxidising agent?

5.18 Laboratory analysis

5.19 Treatments

5.20 Final Reflections

CHAPTER 6 Excessive sulfur dioxide, volatile sulfur compounds and reduced aromas

6.1. Introduction

6.2 The presence and role of sulfur, sulfur dioxide, sulfite and sulfate in wine production

6.3 Excessive sulfur dioxide

6.4 Oxygen management in winemaking

6.5 Reduction in wine – positive and negative

6.6 Hydrogen sulfide

6.7 Prevention of hydrogen sulfide formation

6.8 Treatment for hydrogen sulfide in wine

6.9 Laboratory analysis for sulfur dioxide, hydrogen sulfide and volatile sulfur compounds

6.10 Final reflections

CHAPTER 7 Excessive volatile acidity and ethyl acetate

7.1 Introduction

7.2 Volatile acidity and ethyl acetate

7.3 The controversy of high levels of volatile acidity

7.4 Fixed acids and volatile acids

7.5 Sensory characteristics and detection of volatile acidity

7.6. Legal limits

7.7 Acetic acid bacteria

7.8 Production of acetic acid in wine

7.9 Ethyl acetate

7.10 Prevention of excessive volatile acidity and ethyl acetate.

7.11 Laboratory analysis

7.12 Treatments

7.13 Final reflections

CHAPTER 8 Atypical ageing (ATA) – sometimes called Untypical ageing (UTA)

8.1 Introduction

8.2 The Atypical Ageing Controversy

8.3 The causes of Atypical Ageing and formation pathways

8.4 Sensory detection

8.5 Laboratory detection

8.6 The main viticultural causes of ATA.

8.7 Prevention

8.8 Treatments

8.9 Final reflections

CHAPTER 9 Fermentation in bottle

9.1 Introduction

9.2 Sensory detection

9.3 Alcoholic fermentation in bottle

9.4 Malolactic fermentation (MLF) in bottle.

9.5 Prevention – preparing wine for bottling and the bottling process

9.6 Treatment

9.7 Final reflections

CHAPTER 10 Hazes

10.1 Introduction

10.2 Protein haze

10.3 Microbial hazes

10.4 Metal hazes

CHAPTER 11 Lactic acid bacteria related faults

11.1 Introduction to lactic acid bacteria

11.2 Lactic acid bacteria and their natural sources

11.3 Malolactic fermentation (MLF)

11.4 Undesirable aromas, off-flavours and wine spoilage caused by Lactic Acid Bacteria

11.5 Prevention of lactic acid bacteria related faults

11.5 Analysis

11.6 Final reflections

CHAPTER 12 Smoke taint and other airborne contaminations

12.1 Introduction

12.2 Smoke taint compounds in the atmosphere

12.3 Critical times in the growing season and duration of exposure for smoke taint to impact

12.4 The volatile phenols responsible for smoke taint; their odours and flavours and sensory detection thresholds

12.5 Smoke taint in wines

12.6 Other sources of guaiacol and 4-methyl-gauaiacol in wines

12.7 Laboratory Testing

12.8 Prevention of development of smoke related volatile phenols from affected grapes

12.9 Treatments.

12.10 Other airborne contaminations

12.11 Final reflections

CHAPTER 13 Ladybeetle and brown marmorated stink bug taints

13.1 Introduction

13.2 Methoxypyrazines

13.3 Ladybeetles (also known as ladybirds and ladybugs)

13.4 Brown marmorated stink bug (Halyomorpha halys) taint

13.5 Final reflections

CHAPTER 14 Sundry faults, contaminants, including undesirable compounds from a health perspective and flaws due to poor balance

14.1 Mycotoxins, particularly Ochratoxin A

14.2 Dibutyl phthalate and other phthalates

14.3 Ethyl Carbamate

14.4 Biogenic amines

14.5 Ethyl sorbate and sorbyl alcohol (geraniol) off-odours

14.6 Paper-taste

14.7 Plastic taints – styrene

14.8 Indole

14.9 Geosmin

14.10 2-bromo-4-methylphenol – iodine, oyster taste

14.11 Heat damage

14.12 Matters of balance

14.13 Final reflections

CHAPTER 15 Faults or not? TDN and tartrate crystals

15.2 Tartrate deposits

15.3 Final reflections

CHAPTER 16 Must correction, wine correction and alcohol reduction using membrane technologies

16.1 Introduction

16.2 Membrane processes used in the wine industry

16.3 Clarification

16.4.3 Cross-flow micro filtration

16.5 Membrane Fouling

16.6 Must correction, wine correction and alcohol reduction using membrane technologies.

16.7 Fault correction

16.8 Wine stabilisation and pH adjustment by electrodialysis

16.9 Final redlections

CHAPTER 17 The impact of container and closure upon wine faults

17.1 Introduction

17.2 Glass bottles

17.3 Bottle closures

17.4 The maintenance of adequate fee and molecular SO2 in bottled wine.

17.5 Natural Cork

17.6 Technical corks, including agglomerated corks

17.7 Diam cork closure

17.8 Synthetic closures

17.9 Screwcaps

17.10 VINOLOK

17.11 Some advantages and disadvantages of various closure types

17.12 The bottling operation

17.12 PET bottles.

17.13 Cans

17.14 Bag-in-box

17.15 Final reflections

CHAPTER 18 Best practice for fault and flaw prevention

18.1 The wine industry

18.2 HACCP

18.3 Standard operating procedures (SOPs)

18.4 Traceability

18.5 Winery design

18.6 Cleaning and sanitation

18.7 Good practice winemaking procedures to avoid spoilage, faults and flaws.

18.8 The use of oenological additions and processing aids

18.9 Routine wine analysis

18.10 Final, final reflections

References

APENDIX

BIBLIOGRAPHY

GLOSSARY

USEFUL WEBSITES

| Erscheinungsdatum | 11.06.2021 |

|---|---|

| Verlagsort | Hoboken |

| Sprache | englisch |

| Maße | 175 x 249 mm |

| Gewicht | 1089 g |

| Themenwelt | Sachbuch/Ratgeber ► Essen / Trinken |

| Technik ► Lebensmitteltechnologie | |

| ISBN-10 | 1-118-97906-0 / 1118979060 |

| ISBN-13 | 978-1-118-97906-8 / 9781118979068 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich