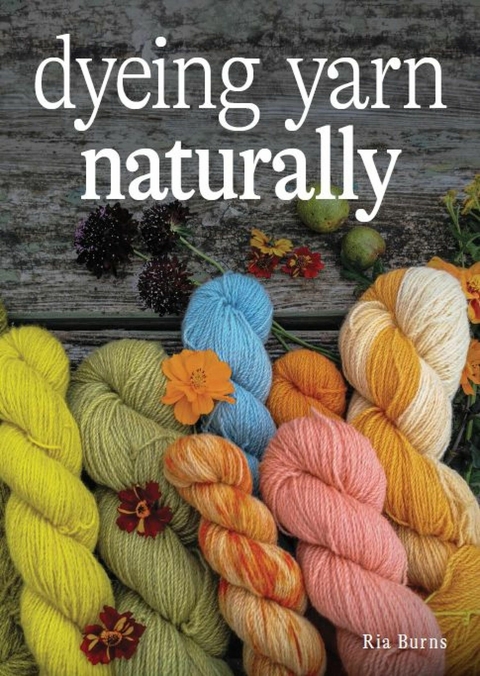

Dyeing Yarn Naturally (eBook)

96 Seiten

The Crowood Press (Verlag)

978-0-7198-4202-3 (ISBN)

Ria Burns is a sustainable knitwear designer-maker who specialises in working with local wool and natural dyes. She has created thousands of colour samples and dye recipes, and her research into plants and colour is widely recognised. Ria teaches natural dyeing and machine knitting workshops.

CHAPTER 2

YARN PREPARATION

The secret to successful natural dyeing is in the preparation. While these steps may take time, it is important not to skip them, no matter how keen you are to start dyeing with a newly foraged or harvested plant.

There are three steps to preparing your yarn for the dye pot: making a hank, scouring and mordanting. Consider these part of the holistic dyeing process, and learn to embrace the slow mindfulness of the craft. Skipping any of these steps will result in a poor dyeing outcome.

Regardless of the format the yarn comes in, they will all need some preparation before dyeing.

You can prepare your yarns in batches to make your processing more efficient, and store them for later use. This means that when you have plants to dye with, you have prepared yarn available for dyeing immediately.

MAKING A HANK

First, you will need to turn your yarn into a suitable format for dyeing, so that it dyes evenly and does not get tangled in the pot. If your yarn is in cake, ball or cone format, you will need to turn it into a hank, which is a large, continuous loop of yarn.

A niddy-noddy is a handheld tool used for making hanks of yarn. They are available in many sizes.

Wrap the yarn around your winding tool (in this case a niddy-noddy) to make a hank, making sure to keep an even tension throughout.

You do not need specialist equipment in order to make a hank, but you can purchase hank winders or a niddy-noddy from specialist suppliers.

A simple way to make a hank without equipment is by using a chair back or your forearm. Regardless of the piece of equipment used, the principle of making a hank is the same.

Wrap the yarn around the implement multiple times, ensuring that the end is secure. Continue until your hank is as large as you need, or until you run out of yarn.

To make a hank of a particular weight, place the cone or ball onto kitchen scales whilst you are making the hank, then stop once the yarn on the scales has decreased by the desired weight. I tend to make 5–10g hanks to use for testing new dyes and recipes, so that there is enough yarn dyed to knit a sample swatch piece.

Tie the two yarn ends together in a knot, then add ties to the hank. I recommend using four ties per hank – two in a loop, and two in a figure eight. This stops the ties from slipping around the hank, and prevents the yarn getting tangled in the dye pot.

Use an undyed sturdy thread, such as cotton, to secure your hank and prevent tangles. Tie two in circles, and two in a figure-eight for extra security.

If your yarn has been purchased already in hank form, check that there are sufficient ties and add more if needed. Do not tie the ties too tightly or you may get patchy dye outcomes.

I prefer to use a sturdy cotton yarn or thread for hank ties, as they are less likely to come undone in the pot. Using a different yarn to the one you are dyeing also helps, as it will be easy to recognise after dyeing, and therefore make it easier to remove later on. Make sure to use an undyed or white yarn for the ties to prevent any potential colour leaching and contamination.

SCOURING

The second step in yarn preparation is called scouring. This is a thorough washing process that removes all of the grease, oil, dirt, lanolin or any finishing treatments from the yarn. Do not skip this step, even if the yarn looks and feels clean, as it will result in a dissatisfactory dye outcome.

Yarn before scouring (left) and after scouring (right). Note how the scoured yarn appears visibly cleaner.

Depending on the type of yarn you have bought, where you have bought it from, and in what format it was purchased, it will require different levels of scouring. Many aspects of natural dyeing are intuitive, and with scouring it will take some trial and error to learn when a yarn has been well scoured.

As an example, the Shetland-Romney lambswool that I use for my knitwear arrives from the mill oiled on a cone, so that it is suitable for machine knitting. As it is wool, it also contains lanolin from the sheep’s fleece and so feels greasy to the touch. The linen yarn used in the scouring example overleaf has been through many factory processes to become a smooth useable yarn, so appears to be fairly clean, but it will have had some treatment applied to it in the spinning process that we will need to remove in the scour.

Scouring involves heating the yarn in water to a high temperature with detergent, until the yarn becomes clean. A stainless steel dye pot on a heat source, such as a hob, is the ideal piece of equipment for scouring. Ensure that the pot is large enough for the yarn to move freely around in the water – the pot in the example photos has a 10-litre capacity.

The method for scouring protein fibres is slightly different to scouring cellulose fibres, so I would recommend that you keep the two types of fibres separate to avoid damaging either yarn.

Scouring protein fibres

The most important point when scouring protein fibres such as wool is to avoid shrinkage and felting which can be caused by extreme changes in heat, and too much agitation. Start cold and increase the temperature slowly, stirring gently to avoid any risk of felting.

Add cold water and detergent to the yarn in your pot. Ensure the pot is large enough for the yarn to move freely around inside.

My preferred detergent for this task is an eco-friendly washing-up liquid. This is strong enough to clean the fibres, without being harmful to the yarn or environment. Use one teaspoon of washing-up liquid per 100g of wool. Add this to a stainless steel pot and fill with cold water and stir. You should use enough water so that the yarn has enough room to move freely around in it. Add the dry hanks of yarn and move it around in the pot so that it absorbs the water.

Place the pot onto your heat source and heat slowly, to around 80°C, or just under a simmer. Over time you will learn what that temperature looks like – there will be steam rising and some bubbles forming. Using a thermometer can be helpful too, to avoid over- or under-heating the pot.

It is important that you do not boil the water, otherwise the yarn could felt and ruin. In my dye studio I use an induction hob, which means I can control the temperature accurately and hold it at a constant 80°C without risk of it boiling over. If you are using a different heat source, such as electric hot plate or gas stove, you will need to pay closer attention to the pot to make sure it doesn’t boil.

Once the water has reached the desired temperature, carefully stir the contents. Continue to scour at this temperature for about an hour, or until the soap bubbles have disappeared and your scouring water has become cloudy. This is a good indicator that the scouring has been successful.

Leave the pot to cool fully before rinsing in lukewarm water – I tend to leave mine overnight. If you remove the yarn while it is still hot and rinse with cold water, you dramatically change the temperature, which can cause felting in protein fibres. Carefully squeeze the yarn under lukewarm running water to remove the scouring water, soap and any residual dirt.

The water after scouring will look dirty. The opacity of the water will vary depending on the type of yarn and how it has been prepared in the spinning process.

You should now have a well scoured yarn, that is ready for the next stage of the process. Occasionally the yarn may be very dirty and you will have to repeat the scouring process – you will be able to tell if this is necessary because the yarn will still feel greasy and the water will not run clear after the first scour.

If you are going to move onto the next stage soon, you can keep the yarn damp in a bucket or container. However, if you won’t be mordanting or dyeing within a few days, I recommend air drying the yarn to avoid mould or mildew forming.

Scouring cellulose fibres

The method for scouring cellulose fibres is similar to that for protein, but as the fibres are processed differently and often coated with sizing and finishing treatments, a different scouring agent is needed.

After scouring cellulose yarns the water may be discoloured due to the way they are processed.

Soda crystals (or washing soda) is a cleaning agent that consists of sodium carbonate, and is my preferred scouring agent for cellulose fibres as it is strong enough to cut through any finishing and sizing treatments on the yarn. Use 2 per cent weight of soda crystals to fibre – for 100g of yarn you will need of 2g of soda.

Use the same heating method for scouring protein fibres. The water will become slightly cloudy, and may change colour to yellow or brown as the yarn becomes clean. As a general rule, cellulose yarns are more tolerant of heat changes, and so you can cool and rinse the yarns and move onto the next step more quickly.

MORDANTING

Most natural dyes require a pre-treatment called a mordant to enable the dye to adhere to the yarn and produce a strong, long-lasting colour that is less likely to fade upon washing or exposure to light. Not all natural dyes require a mordant, but they are recommended for many.

The mordant forms a chemical bond with the yarn, and so once a yarn has been mordanted, it has been mordanted for ever. This means you can mordant in batches and let the yarn dry, saving for later use – make sure to label these yarns, as a...

| Erscheint lt. Verlag | 27.3.2023 |

|---|---|

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Handarbeit / Textiles |

| Sachbuch/Ratgeber ► Freizeit / Hobby ► Heimwerken / Do it yourself | |

| Technik | |

| Weitere Fachgebiete ► Handwerk | |

| Schlagworte | botanical dye • bundle dyeing • Crochet • dyeing • fibre art • foraging • Indigo • Knitting • knitwear • Madder • Natural Dyes • sustainable craft • textile art • weaving • weld • woad • Wool • Yarn • yarn craft • yarn dyeing |

| ISBN-10 | 0-7198-4202-6 / 0719842026 |

| ISBN-13 | 978-0-7198-4202-3 / 9780719842023 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Größe: 17,5 MB

DRM: Digitales Wasserzeichen

Dieses eBook enthält ein digitales Wasserzeichen und ist damit für Sie personalisiert. Bei einer missbräuchlichen Weitergabe des eBooks an Dritte ist eine Rückverfolgung an die Quelle möglich.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich