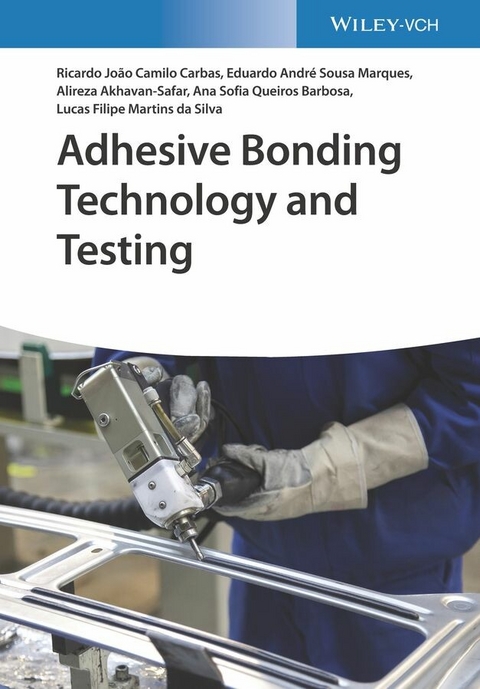

Lucas FM da Silva is Full Professor in the Department of Mechanical Engineering at the Faculty of Engineering of the University of Porto (FEUP) and Director of the Integrated Master in Mechanical Engineering. He obtained his PhD in structural adhesive bonding of composites from the University of Bristol (United Kingdom) in 2004 and Aggregation from FEUP in 2011. Ricardo Carbas is a postdoctoral researcher in Institute of Science and Innovation in Mechanical and Industrial Engineering and an invited lecturer at the Faculty of Engineering of the University of Porto. He obtained his PhD in adhesive bond technologies in 2013 from the University of Porto (Portugal). Eduardo Marques is a postdoctoral researcher in Institute of Science and Innovation in Mechanical and Industrial Engineering and an invited lecturer at the Faculty of Engineering of the University of Porto. He obtained his PhD in adhesive bond technologies in 2016 from the University of Porto (Portugal). Ana Queirós Barbosa is currently a postdoctoral researcher in Institute of Science and Innovation in Mechanical and Industrial Engineering. She obtained her PhD in Reinforcement adhesives in 2017 and MSc in Material Science from the University of Porto (Portugal). Alireza Ahkavan-Safar is currently a postdoctoral researcher in Institute of Science and Innovation in Mechanical and Industrial Engineering. He obtained his PhD in Adhesive mechanical characterization in 2017 from the Iran University of Science and Technology (Iran).

Lucas FM da Silva is Full Professor in the Department of Mechanical Engineering at the Faculty of Engineering of the University of Porto (FEUP) and Director of the Integrated Master in Mechanical Engineering. He obtained his PhD in structural adhesive bonding of composites from the University of Bristol (United Kingdom) in 2004 and Aggregation from FEUP in 2011. Ricardo Carbas is a postdoctoral researcher in Institute of Science and Innovation in Mechanical and Industrial Engineering and an invited lecturer at the Faculty of Engineering of the University of Porto. He obtained his PhD in adhesive bond technologies in 2013 from the University of Porto (Portugal). Eduardo Marques is a postdoctoral researcher in Institute of Science and Innovation in Mechanical and Industrial Engineering and an invited lecturer at the Faculty of Engineering of the University of Porto. He obtained his PhD in adhesive bond technologies in 2016 from the University of Porto (Portugal). Ana Queirós Barbosa is currently a postdoctoral researcher in Institute of Science and Innovation in Mechanical and Industrial Engineering. She obtained her PhD in Reinforcement adhesives in 2017 and MSc in Material Science from the University of Porto (Portugal). Alireza Ahkavan-Safar is currently a postdoctoral researcher in Institute of Science and Innovation in Mechanical and Industrial Engineering. He obtained his PhD in Adhesive mechanical characterization in 2017 from the Iran University of Science and Technology (Iran).

Part A: Instructions for practical demonstrations of adhesive bonding

Adhesive tape

Wetting of different surfaces

Use of superglue to highlight the importance of substrate and environmental conditions

Stresses in a rubber model

Water break test

Plasma treatment and dyne pens

Visual identification of defects

Tap test

Study of real joints used in aeronautical applications

Study of real joints used in automotive applications

Study of real joints used in shipbuilding

Part B: Laboratorial activities on adhesive bonding and report examples

Effect of surface treatment on the strength of bonded joints

Effect of adhesive type in the strength of bonded joints

Effect of adhesive thickness in the performance of bonded joints

Effect of the overlap length on the strength of bonded joints

Mechanical performance of bonded joints bonded with composites

Design of a real bonded joint for service under fatigue conditions

Design of a real bonded joint for service in harsh environmental conditions

Mechanical characterization of a structural adhesive

Part C: Exercises and problems in adhesive bonding

Advantages, disadvantages and applications of adhesive bonding

Surface preparation

Main families of adhesives and their characteristics

Manufacture process of bonded joints

Quality control procedures

Environment health and safety

Design of bonded joints

Durability of bonded joints

Part A: Instructions for practical demonstrations of adhesive bonding

Adhesive tape

Wetting of different surfaces

Use of superglue to highlight the importance of substrate and environmental conditions

Stresses in a rubber model

Water break test

Plasma treatment and dyne pens

Visual identification of defects

Tap test

Study of real joints used in aeronautical applications

Study of real joints used in automotive applications

Study of real joints used in shipbuilding

Part B: Laboratorial activities on adhesive bonding and report examples

Effect of surface treatment on the strength of bonded joints

Effect of adhesive type in the strength of bonded joints

Effect of adhesive thickness in the performance of bonded joints

Effect of the overlap length on the strength of bonded joints

Mechanical performance of bonded joints bonded with composites

Design of a real bonded joint for service under fatigue conditions

Design of a real bonded joint for service in harsh environmental conditions

Mechanical characterization of a structural adhesive

Part C: Exercises and problems in adhesive bonding

Advantages, disadvantages and applications of adhesive bonding

Surface preparation

Main families of adhesives and their characteristics

Manufacture process of bonded joints

Quality control procedures

Environment health and safety

Design of bonded joints

Durability of bonded joints

| Erscheint lt. Verlag | 25.1.2023 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie |

| Schlagworte | adhesive bonding advantages and disadvantages • adhesive bonding experiments • adhesive bonding joint design • adhesive bonding pros and cons • adhesive bonding strength prediction • Adhesive Bonding Technology • adhesive bonding Testing • adhesive bonding textbook • chemical engineering • Chemische Verfahrenstechnik • defect-free bonded joints • Joining, Welding and Adhesion • Kleben • Klebverbindung • Maschinenbau • Maschinenbau - Entwurf • Materials Science • Materialwissenschaften • mechanical engineering • Mechanical Engineering - Design • Metalle u. Legierungen / Verbinden, Schweißen u. Kleben |

| ISBN-10 | 3-527-83800-7 / 3527838007 |

| ISBN-13 | 978-3-527-83800-4 / 9783527838004 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Größe: 9,0 MB

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: PDF (Portable Document Format)

Mit einem festen Seitenlayout eignet sich die PDF besonders für Fachbücher mit Spalten, Tabellen und Abbildungen. Eine PDF kann auf fast allen Geräten angezeigt werden, ist aber für kleine Displays (Smartphone, eReader) nur eingeschränkt geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich